Packaging Printing

We provide high-end printing solutions, combining advanced technology and exquisite craftsmanship to create an exceptional printing experience for your brand.

We provide high-end printing solutions, combining advanced technology and exquisite craftsmanship to create an exceptional printing experience for your brand.

Digital Printer Application Scenarios Analysis: Printing Technology Innovations Showcasing Their Unique Strengths

Analysis of Typical Application Cases of 3 Types of Digital Printers

In today’s era of deep penetration of digital printing technology into various industries, Single Pass Digital Printers, Single Pass UV Printers, and Multi Pass Printers have landed numerous benchmark application cases in different fields through their differentiated technical advantages. This article will disassemble the application value of the three types of equipment through real cases, and visually present their printing effects and production processes with scene-based illustrations to provide reference for industry selection.

Single Pass Digital Printer: Benchmark Application in High-Efficiency Mass Production Scenarios of Corrugated Packaging

Single Pass Digital Printers are characterized by "single-pass imaging, high-speed output, flexible printing, and adaptability to orders of all sizes". Using water-based Pigment inks and Dye inks, they are suitable for printing on porous and water-absorbent materials, and are widely used in packaging printing requiring batch delivery and personalized short-run printing.

A carton manufacturer introduced multiple units of Sunthinks SC series and SE series Single Pass Digital Printers to meet the customized carton needs of the e-commerce industry for "small batches and multiple deliveries". In this project, the printing line speed of a single unit was stably maintained at 30m/min, with a daily production capacity of 50,000 square meters. It can flexibly handle orders ranging from 1 unit per batch to 100,000 units per batch. In September, 10,000 customized corrugated cartons printed for a fresh food e-commerce platform were directly printed with the fresh food brand LOGO, preservation prompts, and variable QR codes (for traceability) using the equipment. No plate-making was required for quick order switching, and the order delivery cycle was compressed from 2-3 days in traditional printing to within 5 hours. The printed finished products had uniform colors, met the warehousing and transportation standards for abrasion resistance, and the use of water-based eco-friendly inks also met the enterprise’s green production requirements.

In October, the customer received an urgent order from a furniture manufacturer for 2,000 corrugated cartons for wooden door export. The order was small in quantity, large in carton size, and urgent in delivery. Generally, large-scale printing factories could not undertake it due to cost issues, but the customer used the Sunthinks SC1800 Digital Printer to complete the order in just 3 hours.

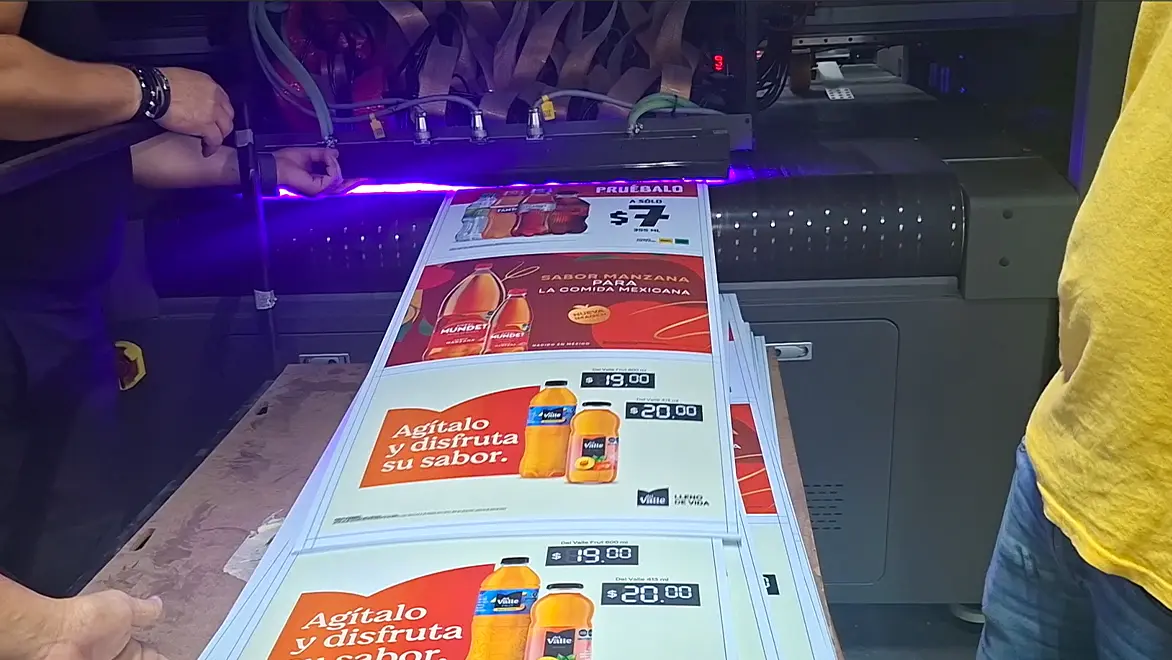

Single Pass UV Printer: Cross-Industry Application Cases with Multi-Material Adaptability

Leveraging UV curing technology, Single Pass UV Printers break material limitations and can achieve high-speed and high-precision printing on rigid materials such as glass, metal, and acrylic. The following cases cover the advertising, decoration, and industrial sectors.

Case 1: Large-Scale Shopping Mall Signage System and POP Billboard Printing Project

During the upgrading and transformation of a commercial complex, more than 1,200 acrylic signage boards of different specifications needed to be produced with a delivery requirement of 3 days. The project adopted a Sunthinks Single Pass UV Printer for printing. The equipment directly printed signage text, brand LOGOs, and patterns on acrylic plates with a thickness of 2-10mm. UV inks cured instantly without the need for subsequent lamination. The printing precision reached 1200dpi, with clear text without burrs and high color saturation. The finished products were scratch-resistant and UV-resistant, suitable for long-term indoor and outdoor use. The equipment’s high-speed output capability ensured that 400+ signage boards could be printed daily, enabling on-time delivery and smooth installation, which was significantly better than the traditional production method of engraving + film laminating.

Case 2: Whole-House Customized Furniture Texture Printing Project

To reduce the procurement cost of high-end wood grain panels, a whole-house customized furniture enterprise introduced a Single Pass UV Printer to print textures on ordinary density boards. The equipment can simulate various precious wood grains and marble textures, with a printing resolution of 1440dpi and a texture restoration rate exceeding 95%. For example, in the printing of wardrobe doors, multi-layer UV ink superposition was used to achieve the concave-convex texture of wood grain. The finished products were highly similar to real solid wood panels, and the UV inks had low VOC emissions, meeting environmental standards. This project reduced panel costs by 40%, realized "on-demand customization and zero inventory" production, and increased annual production capacity by 200,000 panels, becoming one of the enterprise’s core competitive advantages. In addition, in the industrial field, the equipment completed the printing of QR code marks on metal casings for an electronic enterprise. Accurate positioning + fast curing adapted to the production line rhythm, achieving a printing efficiency of 3,000 pieces per hour.

Case 3: Food Packaging Weather-Resistant Printing Project

A casual food enterprise needed to print plastic sealing bags in batches, requiring the printed images to be full of details, abrasion-resistant, odor-free, and meet safety standards. A Sunthinks Single Pass UV Printer was adopted for printing. The equipment’s high-speed output capability met the daily production demand of 100,000 bags. UV inks cured instantly to avoid ink penetration problems, and the printed images were bright in color and odor-free. After testing, the finished products showed no fading or ink loss after being placed in high-temperature and high-humidity environments for 6 months, fully meeting the stringent requirements of food packaging. At the same time, the plate-free feature supported enterprises to quickly launch new packaging to respond to market changes.

Digital Multi Pass Printer: High-Precision Customization Scenario Quality Application Cases

Water-based Multi Pass (multi-pass scanning) packaging printers are packaging digital printing equipment that uses water-based inks and forms complete images by repeatedly scanning and superimposing ink droplets on the substrate surface. Different from Single Pass (single-pass direct printing), their printhead components can move horizontally and pass through the same area multiple times to achieve high precision and high color saturation, making them particularly suitable for high-quality printing needs in the packaging field and small-batch high-quality customization requirements. They are widely used for printing on corrugated cardboard, coated paper, and other materials.

Case 1: A cosmetics company customized multiple SKU of dark and light matte coated paper packaging using a Sunthinks Multi Pass Printer. Through Multi Pass superposition technology, the color difference between printheads was eliminated, achieving uniform and delicate color performance. White text and patterns were printed on dark matte paper to enhance readability and visual impact, and partial highlights were added to the packaging surface to improve luxury. Printing and drying were carried out simultaneously to effectively avoid stacking and adhesion, and the printed products could be directly processed with lamination and hot stamping after printing.

Case Empowers Selection, Technology Adapts to Scenarios

From batch corrugated cartons to shopping mall billboards, furniture customization, food, and cosmetics packaging printing, the application cases of the three types of digital printers fully prove that: Single Pass Digital Printers are suitable for high-efficiency mass production needs; Single Pass UV Printers focus on multi-material all-round printing; and Multi Pass Printers target high-precision customization scenarios. In the future, with the continuous upgrading of technology, the application boundaries of the 3 types of equipment will be further expanded, landing more innovative cases and promoting the printing industry to develop towards higher efficiency, more accuracy, and greater diversity.